Welcome to Kristal Abrasives

Kristal Abrasives incorporated with a vision to manufacture and supply Superabrasives (Diamond & CBN) products to users across the world.

The organisation is backed up by years of Technical expertise in the fabrication of Superabrasive tooling and technical support to offer the client tailor made solutions pertaining to the uniqueness of their products.

As India sets the stage with more and more industrialization, we pledge our dedication and expertise to cater to the Industry with products of precision at best prices and unmatched delivery schedules.

We invite you to try out our products, which we are sure will match to your requirements.

Our Brands

About us

Kristal Abrasives broadly Manufactures and supplies to two broad Industrial segments, Such are the stone Industries as well as the engineering Industries.

With a backup of decades of Industrial Expertise in the above sectors, we are marching ahead to be global leaders in our segment of activity.

The company posesses the best of machines and manpower to deliver nothing but the best.

For the Stone industry, the company manufactures Diamond Wires and Beads, Diamond Saw & Segments, Diamond Polishing Tools & Diamond Hand Held Grinder, Diamond Core Drills and Diamond Grinding Tools.

For the metal working, industry the company manufactures Diamonds & cBN Grinding Wheels, Honing Sticks, PCD & PcBN Tools, Lapping Pastes, Diamond Cut off Wheels.

For the Glass Industries, we manufacture Diamond Grinding Wheels, Polishing Wheels, Tube Drills, Trepanning Tools Diamond Rim Blades & Diamond Calibrating Rolls.

In all, we will do our best to provide you with a cost effective solution for your needs.

Our Clients

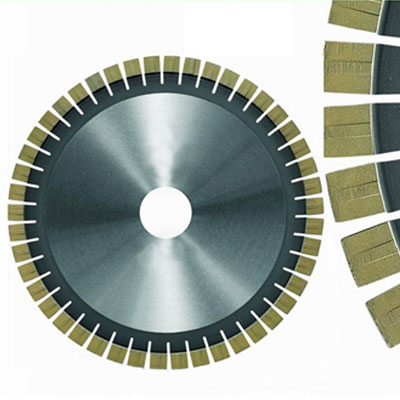

- Diamond Saw Blades & Segments

- Diamond Wires & Beads

- Diamond Multi Wire

- Diamond Special Tools

- Diamond & CBN Grinding Wheels & Tools for Metal Working

- Diamond & CBN Honing Sticks

- Diamond Wheels for the Glass & Ceramics

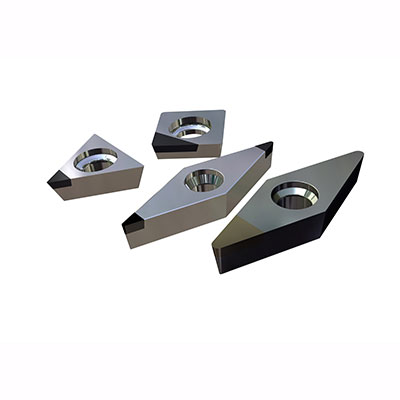

- PCD & PCBN Tools for the Automobile Sector

- Diamond Core Drills & Segments

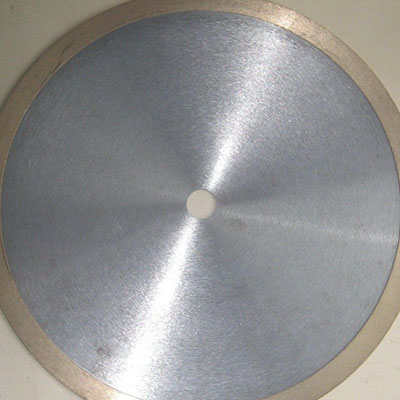

Diamond Saw Blades & Segments

Diamond Concrete Saws

| Diameter | Product | Size of Segment | Number of Segment |

|---|---|---|---|

| 300 mm | Concrete and Asphalt Saw | 3,2x10x40 mm | 18 |

| 350 mm | 3,2x10x40 mm | 21 | |

| 400 mm | 3,6x10x40 mm | 24 | |

| 450 mm | 3,8x10x40 mm | 26 | |

| 800 mm | Concrete Saw | 4,5x10x40 mm | 46 |

| 800 mm | 5,0x10x40 mm | 46 | |

| 800 mm | 5,5x10x40 mm | 46 | |

| 1000 mm | 4,5x10x40 mm | 56 | |

| 1000 mm | 5,0x10x40 mm | 56 | |

| 1200 mm | 4,5x10x40 mm | 64 |

Diamond Grooving Saws

| Diameter | Product | Size of Middle Segment | Size of side Segment | Number of Segment |

|---|---|---|---|---|

| 350 mm | Grooving Saws | 3,2x10x40 mm | 5,0x10x40-45o mm | 18 -21- 18 |

| 350 mm | 3,8x10x40 mm | 5,0x10x40-45o mm | 18 -21- 18 | |

| 350 mm | 6,5x10x40 mm | 5,0x10x40-45o mm | 18 -21- 18 |

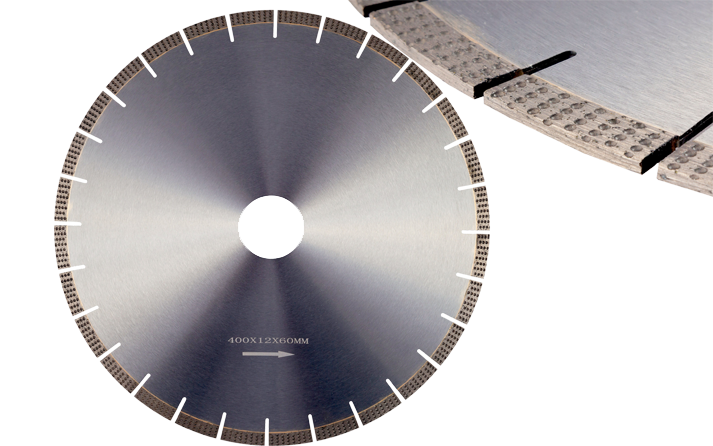

Diamond Granite Sizing Blades

| Diameter of the Saws | Sheet Segment | Size of Segment W x H x L | Number of Segment |

|---|---|---|---|

| 300 mm | Normal / Standard | 3,2x10x40 | 21 |

| 300 mm | Normal / Standard | 3,2x15x40 | 21 |

| 350 mm | Normal / Standard | 3,2x10x40 | 25 |

| 350 mm | Normal / Standard | 3,2x15x40 | 25 |

| 400 mm | Normal / Standard | 3,6x10x40 | 28 |

| 400 mm | Normal / Standard | 3,6x15x40 | 28 |

| 450 mm | Normal / Standard | 3,8x10x40 | 32 |

| 450 mm | Normal / Standard | 3,8x15x40 | 32 |

| 500 mm | wide | 4,5x10x40 | 30 |

| 500 mm | Narrow | 4,5x10x40 | 36 |

| 550 mm | wide | 4,5x10x40 | 36 |

| 550 mm | Narrow | 4,5x10x40 | 42 |

| 600 mm | wide | 4,5x10x40 | 36 |

| 600 mm | Narrow | 4,5x10x40 | 42 |

| 700 mm | wide | 5,5x10x40 | 40 |

| 700 mm | Narrow | 7.1-6,0x12,5x24 | 50 |

| 800 mm | wide | 5,5x10x40 | 46 |

| 800 mm | Narrow | 7.6-6,5x12,5x24 | 57 |

Diamond ST Horizontal Blades

| Diameter of the Saws | Sheet Segment | Size of Segment W x H x L | Number of Segment |

|---|---|---|---|

| 400 mm | wide | 5,5x10x40 | 24 |

| 400 mm | wide | 6,5x10x40 | 24 |

| 400 mm | wide | 8x8x40 | 24 |

| 450 mm | wide | 5,5x10x40 | 26 |

| 450 mm | wide | 6,5x10x40 | 26 |

| 450 mm | wide | 8x8x40 | 26 |

| 500 mm | wide | 5,5x10x40 | 30 |

| 500 mm | wide | 6,5x10x40 | 30 |

| 500 mm | wide | 8x8x40 | 30 |

| 550 mm | wide | 5,5x10x40 | 32 |

| 550 mm | wide | 6,5x10x40 | 32 |

| 550 mm | wide | 8x8x40 | 32 |

| 600 mm | wide | 5,5x10x40 | 36 |

| 600 mm | wide | 6,5x10x40 | 36 |

| 600 mm | wide | 8x8x40 | 36 |

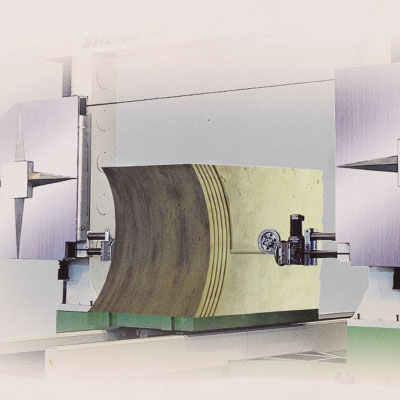

Diamond Granite Multiblades

Kristal Abrasives takes product standards as the basic in the production of its Multiblade Saws, and has completed necessary investment for this purpose. Products with high quality standards are manufactured by using automatic welding, automatic voltage and balance machines. All saws from the production line are delivered to the customer with voltage quality control report.

Multiblades Rotation Table

| Diameter | Flange Diameter | Peripheral Speed m/Sec | ||||

|---|---|---|---|---|---|---|

| 25 | 30 | 35 | 40 | 45 | ||

| 1200 | 300 | 398 | 478 | 557 | 637 | 717 |

| 1250 | 300 | 382 | 459 | 535 | 611 | 688 |

| 1300 | 300 | 367 | 441 | 514 | 588 | 611 |

| 1400 | 300 | 341 | 409 | 478 | 546 | 614 |

| 1500 | 300 | 318 | 382 | 446 | 510 | 573 |

| 1600 | 300 | 299 | 358 | 418 | 478 | 537 |

| 1650 | 350 | 290 | 347 | 405 | 463 | 521 |

| 1700 | 350 | 281 | 337 | 393 | 450 | 506 |

| 1750 | 350 | 273 | 328 | 382 | 437 | 491 |

| 1800 | 400 | 265 | 318 | 372 | 425 | 478 |

| 2000 | 400 | 239 | 287 | 334 | 382 | 430 |

Granite Multiblades

| Diameter of the Saws | Type of saw | Size of Segment W x H x L | Number of Segment |

|---|---|---|---|

| 1000 mm | Multiblade | 7.1-6,0x12,5x24 | 70 |

| 1100 mm | Multiblade | 7.6-6,5x12,5x24 | 74 |

| 1200 mm | Multiblade | 7.6-6,5x12,5x24 | 80 |

| 1300 mm | Multiblade | 7.6-6,5x12,5x24 | 88 |

| 1400 mm | Multiblade | 8.1-7,0x12,5x24 | 92 |

| 1500 mm | Multiblade | 8,6-7,5x12,5x24 | 100 |

| 1600 mm | Multiblade | 8,6-7,5x12,5x24 | 104 |

| 1800 mm | Multiblade | 9,6-8,5x12,5x24 | 120 |

| 2000 mm | Multiblade | 10,1-9x12,5x24 | 132 |

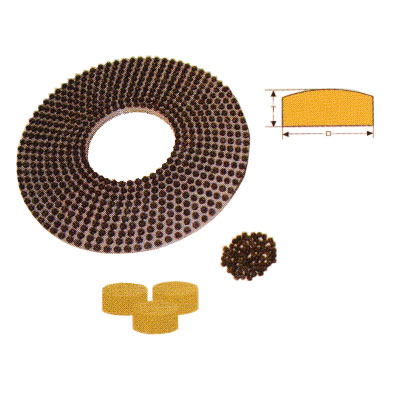

Diamond Wires & Beads

Diamond Wire with Spring (Dry Cutting)

Kristal Abrasives Dry Cutting Wires are Manufactured as an alternative solution to heavy working conditions in mines where access to water is hard and in winter months.

| Diameter | Diamond Covered Areas | Assembling | Number of Beads 1m/Num | Material | Speed of Rotat. m/Second | Cutting Speed m2/Hour | Production m2/m |

|---|---|---|---|---|---|---|---|

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 27 | Biege Marble | 45 | 6-10 | 50-80 |

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 27 | Travertine | 45 | 9-12 | 70-90 |

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 27 | Limestone | 45 | 10-14 | 70-100 |

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 27 | Siliceous Stone | 45 | 9-14 | 40-60 |

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 30 | Biege Marble | 45 | 5-9 | 60-90 |

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 30 | Travertine | 45 | 7-10 | 70-100 |

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 30 | Limestone | 45 | 9-12 | 80-120 |

| 11 mm | 1,5 mm | Spring-Dry-Cutting | 30 | Siliceous Stones | 45 | 8-12 | 50-80 |

Diamond Plastic Coated Mono Wire

Kristal Abrasives Manufactures Plastic Coated Diamond wires in 11 mm, 8,5 mm and 7,3 mm sizes and 30-bead, 35-bead and 40-bead options acoording to your stone.

Kristal Abrasives extended its product range with endless wire (closed circle) Production according to consumer demands and the machines to be used.

| Diameter | Diamond Covered Areas | Assembling | Number of Beads 1m/Num | Kind of Product | Material | Speed of Rotat. m/Second | Cutting Speed cm2/Hour | Production m2/m |

|---|---|---|---|---|---|---|---|---|

| 11 mm | 1,5 mm | With Spring-Without Spring | 30 | Plastic Coated Wire | Begie Marble | 35-45 | 80-190 | 55-85 |

| 11 mm | 1,5 mm | With Spring-Without Spring | 35 | Plastic Coated Wire | Travertine - Limestone | 35-45 | 100-220 | 50-90 |

| 8,5 mm | 1,25 mm | Without Spring | 30 | Plastic Coated Wire | Begie Marble | 35-45 | 100-210 | 50-75 |

| 8,5 mm | 1,25 mm | Without Spring | 35 | Plastic Coated Wire | Travertine - Limestone | 35-45 | 120-240 | 45-80 |

| 7,3mm | 1,15 mm | Without Spring | 35 | Plastic Coated Wire | Begie Marble-Travertine - Limestone | Shape Cutting |

Diamond Mono Wire

Diamond Plastic Coated Wire for Fixed Machine

Kristal Abrasives Coated Monowires enables fast and efficient production in smoothing and shrinking granite block sufaces.

| Diameter | Diamond Covered Areas | Assembling | Number of Beads 1m/Num | Kind of Product | Material | Speed of Rotat. m/Second | Cutting Speed m2/Hour | Production m2/m |

|---|---|---|---|---|---|---|---|---|

| 11 mm | 1,5 mm | With Spring | 40 | Plastic Coated Wire | Soft | 20-30 | 0,8-1,2 | 10-15 |

| 11 mm | 1,5 mm | With Spring | 35 | Plastic Coated Wire | Hard | 20-30 | 0,8-1,2 | 6-12 |

| 8,5 mm | 1,25 mm | Without Spring | 40 | Plastic Coated Wire | Soft | 20-30 | 0,9-1,3 | 8-12 |

| 8,5 mm | 1,25 mm | Without Spring | 35 | Plastic Coated Wire | Hard | 20-30 | 0,9-1,3 | 4-10 |

Diamond Plastic Coated Shape Cutting Wire

Kristal Abrasives Coated Wires used in profile machine enables smooth surfaces in special models to be applied.

| Diameter | Diamond Covered Areas | Assembling | Number of Beads 1m/Num | Kind of Product | Material | Speed of Rotat. m/Second | Cutting Speed m2/Hour | Production m2/m |

|---|---|---|---|---|---|---|---|---|

| 8,5 mm | 1,25 mm | Without Spring | 40 | Plastic Coated Wire | Soft | 20-30 | 0,5-0,7 | 8-14 |

| 8,5 mm | 1,25 mm | Without Spring | 35 | Plastic Coated Wire | Hard | 20-30 | 0,5-0,7 | 6-12 |

| 7,3 mm | 1,15 mm | Without Spring | 40 | Plastic Coated Wire | Soft | 20-30 | 0,6-0,8 | 6-12 |

| 7,3 mm | 1,15 mm | Without Spring | 35 | Plastic Coated Wire | Hard | 20-30 | 0,6-0,8 | 4-10 |

Diamond Quarry Wire

Diamond Plastic Coated Quarry Wire

Kristal Abrasives Manufactures Plastic Coated Diamond Wires with a size of 11 mm and with 35- and 40-bead choices, in order to be used for cutting granite.

| Diameter | Diamond Covered Areas | Assembling | Number of Beads 1m/Num | Kind of Product | Material | Speed of Rotat. m/Second | Cutting Speed m2/Hour | Production m2/m |

|---|---|---|---|---|---|---|---|---|

| 11 mm | 1,5 mm | Plastic/With Spring - Without Spring | 40 | Plastic Coated Wire | Soft Granite | 20-30 | 3-6 | 8-18 |

| 11 mm | 1,5 mm | Plastic/With Spring - Without Spring | 40 | Plastic Coated Wire | Middle Hard Granite | 20-30 | 2-5 | 6-12 |

| 11 mm | 1,5 mm | Plastic/With Spring - Without Spring | 35 | Plastic Coated Wire | Hard Granite | 20-30 | 1-4 | 4-9 |

Diamond Rubber Coated Quarry Wire

Kristal Abrasives Rubber Coated Wires are Manufactures with a size of 11 mm and with 35- and 40-bead choices, in a way that keep cutting performance and productivity in maximum level.

| Diameter | Diamond Covered Areas | Assembling | Number of Beads 1m/Num | Kind of Product | Material | Speed of Rotat. m/Second | Cutting Speed m2/Hour | Production m2/m |

|---|---|---|---|---|---|---|---|---|

| 11 mm | 1,5 mm | Rubber/With Spring - Without Spring | 40 | Rubber Coated Wire | Soft Granite | 20-30 | 3-6 | 8-18 |

| 11 mm | 1,5 mm | Rubber/With Spring - Without Spring | 40 | Rubber Coated Wire | Middle Hard Granite | 20-30 | 2-5 | 6-12 |

| 11 mm | 1,5 mm | Rubber/With Spring - Without Spring | 35 | Rubber Coated Wire | Hard Granite | 20-30 | 1-4 | 4-9 |

Diamond Concrete Wire

Kristal Abrasives concrete cutting wires, Manufactured with plastic and rubber Coating, enable high performance and maximum efficiency in cutting concrete with or without reinforcement.

Kristal Abrasives Concrete cutting wires are Manufactured with 40 beads and spring in the standard product group of a diameter of 11 mm.

| Diamention of Beads | Assembling | Number of Beads 1m/Num | Materials | Speed of Rotat. m/Second | Cutting Speed m2/Hours | Production m2/m | ||

|---|---|---|---|---|---|---|---|---|

| Diameter | Diamond Covered Areas | Height | ||||||

| 11 mm | 1,5 mm | 6 mm | Plastic coated/With Spring | 40 | Reinforced Concrete | 20-30 | 1,0-1,5 | 1-4 |

| 11 mm | 1,5 mm | 6 mm | Rubber coated/With Spring | 40 | Reinforced Concrete | 20-30 | 1,0-1,5 | 1-4 |

Diamond Multi Wire

Diamond Multi Wire

Kristal Abrasives has expanded its product range by adding plastic injection machine to its investments. It Manufactures superior quality products by combining its technology with its experience in the sector.

| Diameter | Diamond Covered Areas | Assembling | Number of Beads 1m / Num | Kind of Product | Maerial | Speed of Rotat. M / Second | Cutting Speed m2 / Hours | Production m2 / m |

|---|---|---|---|---|---|---|---|---|

| 7,3 mm | 1,15 mm | Without Spring | 40 | Plastic Coated Wire | Mixed Granite | 22-26 | 0,6 - 1,0 | 8 - 12 |

| 8,5 mm | 1,15 mm | Without Spring | 35 | Plastic Coated Wire | Mixed Granite | 22-26 | 0,8 - 1,2 | 06 - 10 |

| 8,5 mm | 1, 5 mm | Without Spring | 40 | Plastic Coated Wire | Mixed Granite | 22-26 | 0,5 - 0,9 | 09 - 13 |

| 8,5 mm | 1,25 mm | Without Spring | 35 | Plastic Coated Wire | Mixed Granite | 0,6 - 1,0 | 8 – 12 | 09 - 13 |

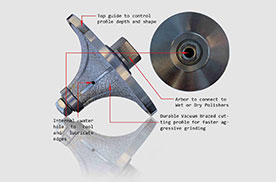

Diamond Special Tools

Diamond Profiles

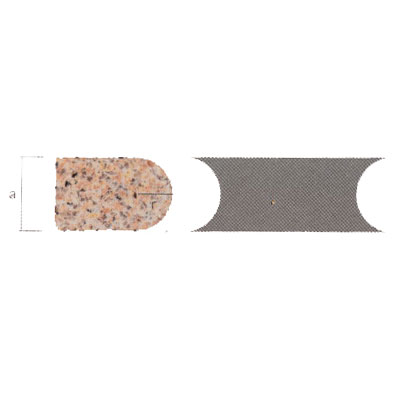

Full Bullnose Profiles

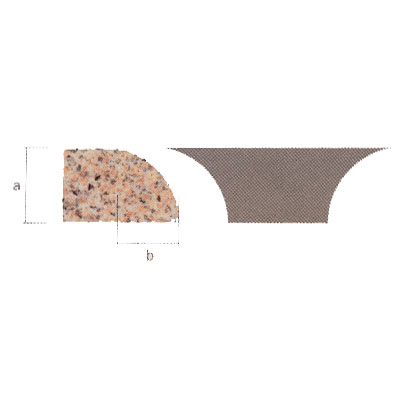

Half Bullnose Profiles

Full Bullnose Profiles

| Diameter | Product | a | r |

|---|---|---|---|

| 320 mm | 2 cm Bullnose Profile | 2 cm | 1 cm |

| 320 mm | 3 cm Bullnose Profile | 3 cm | 1,5 cm |

| 320 mm | 4 cm Bullnose Profile | 4 cm | 2 cm |

| 320 mm | 5 cm Bullnose Profile | 5 cm | 2,5 cm |

| 320 mm | 6 cm Bullnose Profile | 6 cm | 3 cm |

Half Bullnose Profiles

| Diameter | Product | a | r |

|---|---|---|---|

| 320 mm | 1 cm Bullnose Profile | 1 cm | 1 cm |

| 320 mm | 1,5 cm Bullnose Profile | 1,5 cm | 1,5 cm |

| 320 mm | 2 cm Bullnose Profile | 2 cm | 2 cm |

| 320 mm | 2,5 cm Bullnose Profile | 2,5 cm | 2,5 cm |

| 320 mm | 3 cm Bullnose Profile | 3 cm | 3 cm |

Diamond Canal Saws

| Diameter | Product | Size of Canal | Size of Segment | Prize of segement |

|---|---|---|---|---|

| 320 mm | Saw of Canal | 8 mm | 8x8x24 mm | 39/Pcs |

| 320 mm | Saw of Canal | 10 mm | 8x8x24 mm | 39/Pcs |

| 320 mm | Saw of Canal | 15 mm | 8x8x15 mm | 59/Pcs |

| 320 mm | Saw of Canal | 20 mm | 7x8x20 mm | 62/Pcs |

| 320 mm | Saw of Canal | 25 mm | 8x8x24 mm | 59/Pcs |

| 320 mm | Saw of Canal | 30 mm | 8x8x30 mm | 59/Pcs |

| 320 mm | Saw of Canal | 10 mm / 45o | 8x8x24 mm | 39/Pcs |

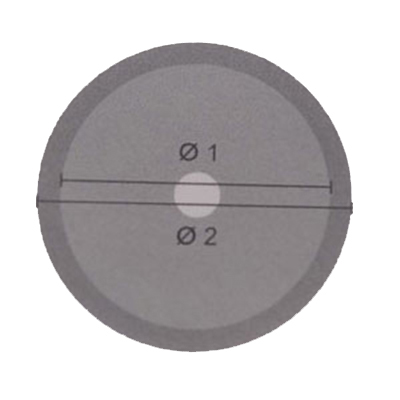

Diamond Tools for Washbasin

Kristal Abrasives Washbasin Tools are produced as two different types for customer requirements.

| Products | Diameter |

|---|---|

| Tools for Washbasin (bevelled) | ∅1=345 mm - ∅2=380 mm |

| Tools for Canal Washbasin | ∅1=345 mm - ∅2=420 mm |

Diamond Calibrations

Diamond Calibrating Rollers

Calibrating Roller Segment for Granite.

Diamond Turbo Saws and Cup Wheel

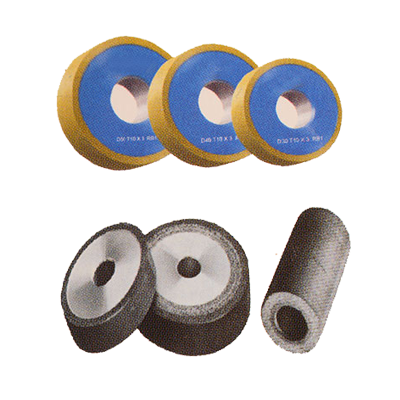

Diamond & CBN Grinding Wheels & Tools for Metal Working

Diamond Cup Wheels

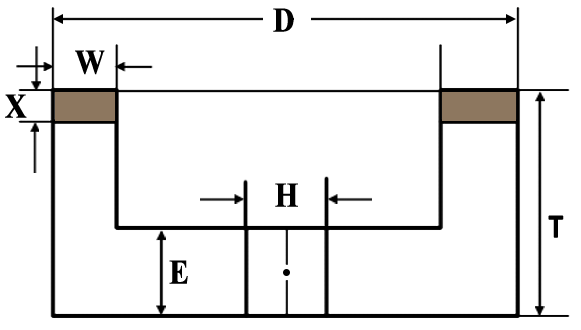

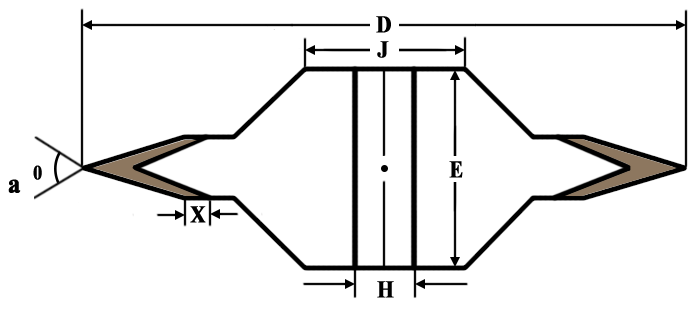

Type 6A2

| D | W | X | T | H * | E |

|---|---|---|---|---|---|

| 30 | 3,5 | 3,5 | 20 | * | 8 |

| 40 | 3,5 | 3,5 | 20 | * | 8 |

| 75 | 3,5 | 3,5 | 20 | * | 10 |

| 90 | 3,5 | 3,5 | 20 | * | 10 |

| 100 | 5,10 | 3,5 | 20 | * | 10 |

| 125 | 5,10 | 3,5 | 20 | * | 10 |

| 150 | 5,10,15,20 | 3,5 | 20 | * | 13 |

| 175 | 5,10,15,20 | 3,5 | 20,30 | * | 13 |

| 200 | 5,10,15,20 | 3,5 | 20,30 | * | 13 |

| 250 | 5,10,15,20 | 3,5 | 20,30 | * | 13 |

| 300 | 5,10,15,20 | 3,5 | 20,30 | * | 13 |

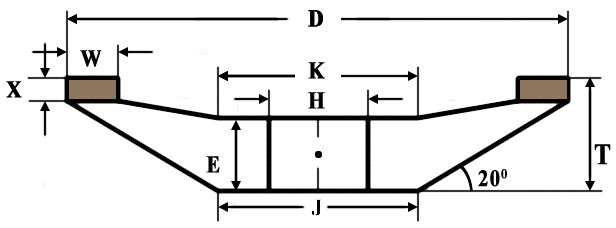

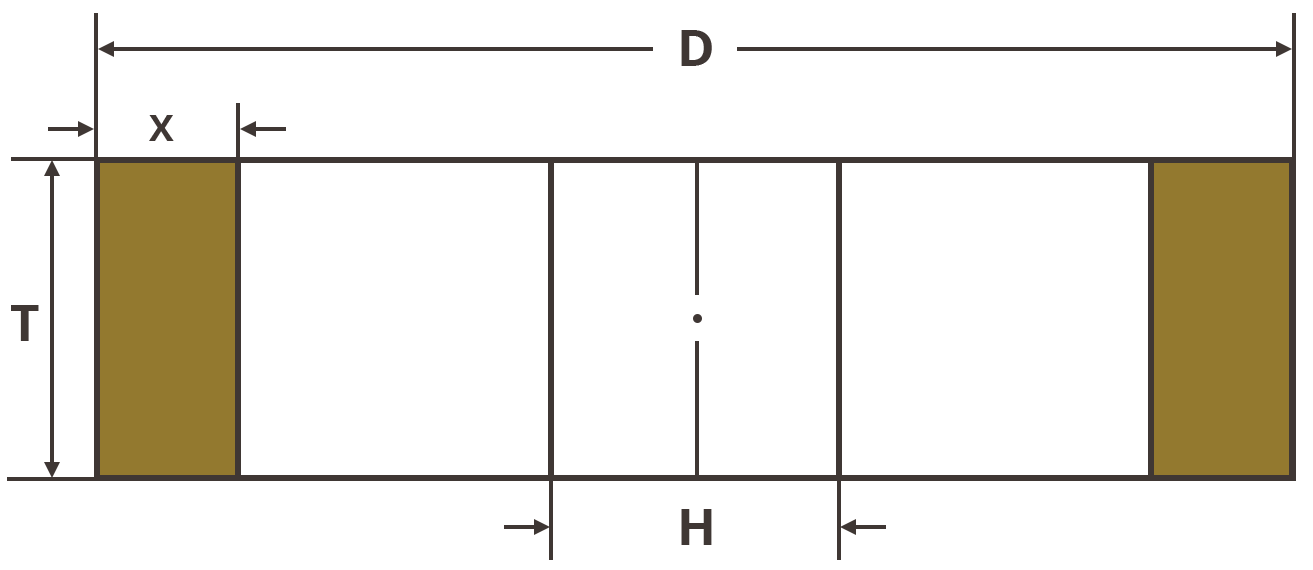

Diamond Saucer Wheels

Type 12A2

| D | W | X | T | E | K | J | H * |

|---|---|---|---|---|---|---|---|

| 50 | 3,5 | 2,3 | 7 | 5 | 25 | 25 | 10 |

| 75 | 3,5 | 2,3 | 9 | 6 | 30 | 30 | 20 |

| 100 | 3,5 | 2,3 | 10 | 6 | 35 | 35 | 31.75 |

| 125 | 3,5 | 2,3 | 14 | 8 | 40 | 40 | 31.75 |

| 150 | 5,10 | 3,5 | 16 | 9 | 40 | 50 | 31.75 |

| 175 | 5,10 | 3,5 | 18 | 10 | 50 | 60 | 31.75 |

| 200 | 5,10 | 3,5 | 20 | 11 | 60 | 80 | 31.75 |

| 250 | 5,10 | 3,5 | 33 | 13 | 80 | 95 | 31.75 |

| 300 | 5,10 | 3,5 | 33 | 13 | 90 | 105 | 31.75 |

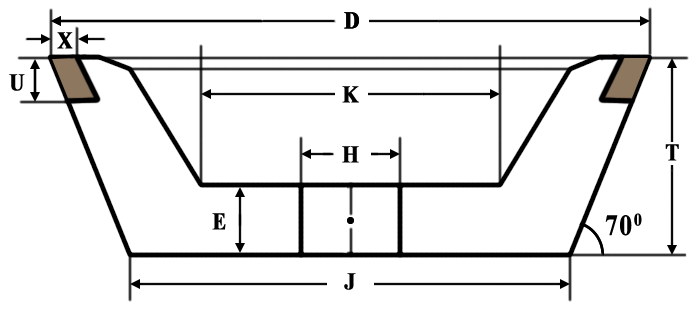

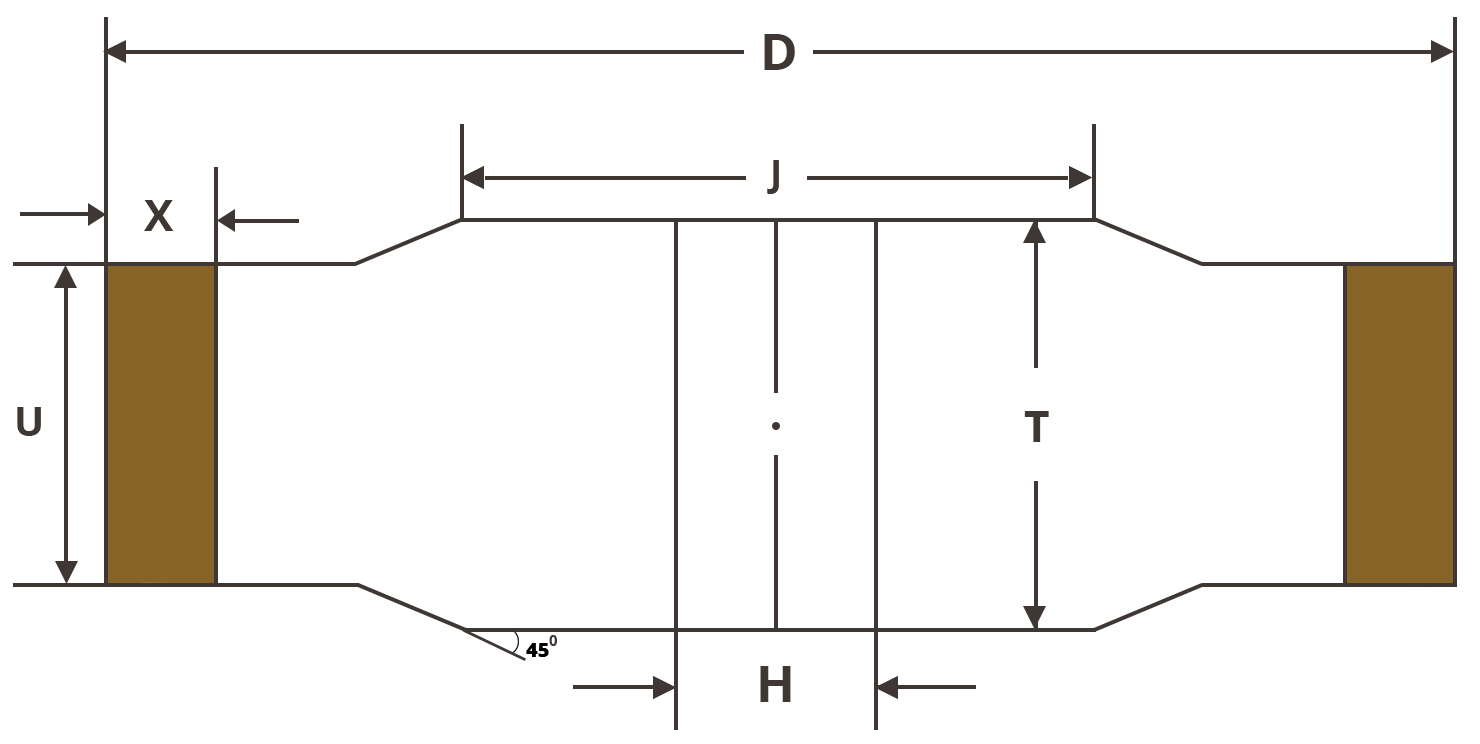

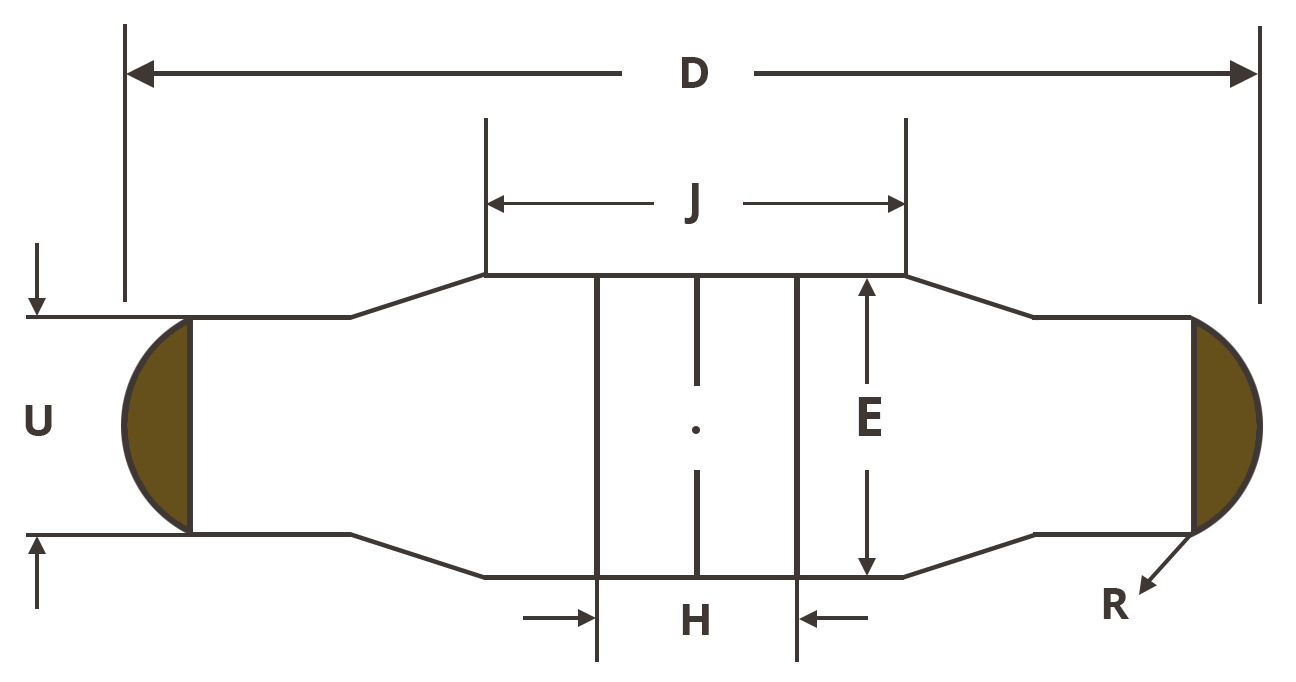

Diamond Flaring Cup Wheels

Type 11V9 70°/45°

| D | X | U | T | E | K | J | H * |

|---|---|---|---|---|---|---|---|

| 90 | 2,3 | 6,10 | 35 | 10 | 52 | 64 | 31.75 |

| 100 | 2,3 | 6,10 | 35 | 10 | 60 | 75 | 31.75 |

| 125 | 2,3 | 6,10 | 40 | 10 | 80 | 95 | 31.75 |

| 150 | 2,3 | 6,10 | 40 | 10 | 95 | 115 | 31.75 |

Diamond Peripheral Wheels

Type 1A1

Type 14A1

Type 14EE1

Type 14F1

Type 1A1 & 14A1

| D | H * | X | T | U |

|---|---|---|---|---|

| 75,100 | 31.75 | 3,5 | 6 | 6,8,10 |

| 125,150 | 31.75 | 3,5 | 6,10 | 6,8,10 |

| 175,200 | 31.75 | 3,5 | 6,10,15 | 8,10,15 |

| 250,300 | 31.75 | 3,5 | 10,15,20 | 10,15,20 |

Type 14EE1 & 14F1

| D | H * | X | alpha/R ** | U | E * |

|---|---|---|---|---|---|

| 75,100 | 31.75 | 3,5 | ** | 6 | 8 |

| 125,150 | 31.75 | 3,5 | ** | 6,10 | 10 |

| 175,200 | 31.75 | 3,5 | ** | 6,10,15 | 10,15 |

| 250,300 | 31.75 | 3,5 | 10,15,20 | 10,15 |

Diamond Internal Wheels

Type 1A1

| D | H * | X | T/U |

|---|---|---|---|

| 6,8 | 4 | 2 | 4,6 |

| 10,12 | 6 | 2 | 6,8,10 |

| 15,20,25 | 6,10 | 2 | 6,8,10 |

| 30,40 | 10,16,20 | 3 | 6,8,10 |

| 50 | 10,16,20 | 3 | 6,8,10 |

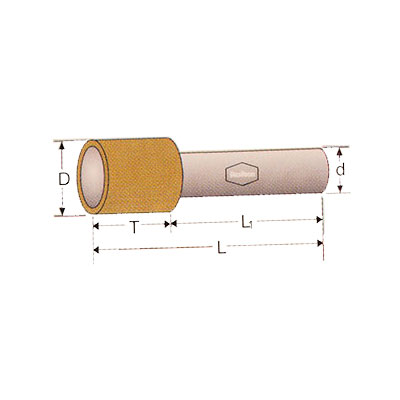

Diamond Mounted Points

Type 1A1W

| D | L1 * | X | d | T |

|---|---|---|---|---|

| 3,4,6 | 25 | 1,2 | 6 | 5,8 |

| 8,10 | 30 | 2 | 6 | 5,8,10 |

| 12,15 | 35 | 3 | 6,8 | 8,10 |

| 18,20 | 35 | 3 | 8,10 | 10,5 |

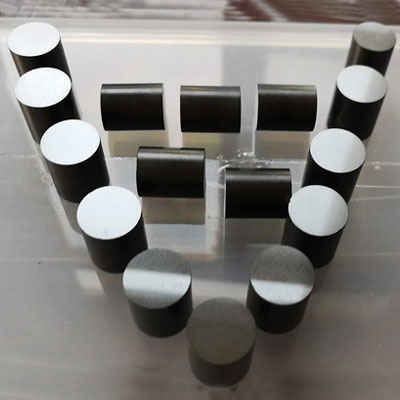

Diamond Pellets

| D | T |

|---|---|

| 4,5 | 3 |

| 6 | 3 |

| 8 | 3,5 |

| 10 | 3,5 |

Diamond & CBN Honing Sticks

Diamond Honing Stone, Diamond Honing Stick, Bar, Rod, Steel, Slate, Mandrel

We widely used in processing of Black-metal, High-speed steel (HSS), Stainless steel, Alnico, Chrome and Limonite etc. The honing stone/sticks applied in the field of Molding, Compressor, Automobile Components and Sartorial manufacture. Diamond and CBN Honing Stone also used in auto parts (Connecting Rod, Cylinder, Fork, Rocker Arm), Sewing parts, Mould making, Carbide tooling and compressor industry.

Diamond Honing Stone, Honing Stick, Honing Bar, Rod, Steel.

Diamond Honing Stone, Honing Stick, Honing Bar, Rod, Steel.

Diamond Honing Stone, Honing Stick, Honing Bar, Rod, Steel.

Diamond Honing Stone, Honing Stick, Honing Bar, Rod, Steel.

.jpg)

Mandrel

.jpg)

Mandrel

Mandrel

Mandrel

Mandrel Packagings

.jpg)

Diamond Honing Stone L6,L7,L8

.jpg)

Diamond Honing Stone

.jpg)

Diamond Honing Stone P28NM55

.jpg)

Diamond Honing Stone K6DM

.jpg)

Diamond Honing Stone K8, D126

.jpg)

CBN Honing Stone

.jpg)

Diamond Honing Stone L Series

.jpg)

220 Honing Stones

Diamond Honing Packing

Material to be grind:

Diamond Honing Stone: Cast iron, Babbit, Brass.bronze and alloy, Glass, Ceramics etc.

CBN Honing Stone: Tool steel, Die steel, Harden steel, HT alloy steel, high-chromium cast iron etc.

Horizontal Diamond Honing Stones

K series Diamond Honing Stone

| Series No. | PHK3 | PHK4 | PHK5 | PHK6 | PHK8 | PHK10 | PHK12 | PHK16 | PHK20 | PHAK20 | PHAK30 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Stone length | 15 | 15 | 18 | 19 | 32 | 32 | 45 | 57 | 63 | 63 | 63 |

| Bore diameter | 2.5-3 | 3-4 | 4-5 | 5-6 | 6-8 | 8-9.5 | 9.5-13 | 13-16 | 16-19 | 19-32 | 32-40 |

| Adapter | PHK3 | PHK4 | PHK5 | PHK6 | PHK8 | PHK10 | PHK12 | PHK16 | PHK20 | PHAK20 | PHAK30 |

B series Diamond Honing Stone

| Series No. | PHB8 | PHB10 | PHB12 | PHB14 | PHB16 | PHB20 | PHAB20 | PHAB30 |

|---|---|---|---|---|---|---|---|---|

| Stone length | 47 | 47 | 60 | 70 | 85 | 95 | 95 | 95 |

| Bore diameter | 6-8 | 8-9.5 | 9.5-13 | 9.5-13 | 13-16 | 16-19 | 19-32 | 32-40 |

| Adapter | PHB8 | PHB10 | PHB12 | PHB14 | PHB16 | PHB20 | PHAB20 | PHAB30 |

L series Diamond Honing Stone

| Series No. | L3 | L4 | L5 | L6 | L8 | L10 | L12 | L16 | L20 |

|---|---|---|---|---|---|---|---|---|---|

| Stone length | 25 | 25 | 32 | 35 | 57 | 57 | 88 | 114 | 114 |

| Bore diameter | 1.9-3 | 3-4 | 4-5 | 5-6 | 6-8 | 8-9.5 | 9.5-13 | 13-16 | 16-32 |

| Adapter | L3 | L4 | L5 | L6 | L8 | L10 | L12 | L16 | L20 |

Honing Stones parameters

| Code | PHNM75 | PHNM55 | PHNM50 | PHNM45 | PHNM65 | PHNM85 | PHNM95 | PHNM15 | PHNM05 | PHNM04 | PHNM005 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grit size | 80# | 100# | 120# | 140# | 180# | 240# | 280# | 300# | 400# | 500# | 800# |

| PEPA Grit | D181 | D151 | D126 | D107 | D91 | D64 | D54 | D48 | D35 | D25 | D15 |

| Roughness | 2.0-1.6 | 1.6-1.4 | 1.6-1.4 | 1.4-1.3 | 1.3-1.0 | 1.0-0.8 | 0.8-0.7 | 0.8-0.6 | 0.6-0.4 | 0.4-0.2 | 0.2-0.1 |

| Stock Removal | 0.1-0.2 | 0.05-0.1 | 0.05-0.1 | 0.05-0.1 | 0.03-0.1 | 0.03-0.07 | 0.02-0.035 | 0.015-0.03 | 0.01-0.015 | 0.01-0.015 | 0.005-0.01 |

Vertical Diamond and Borazon/CBN Honing Stones

| Length L | 200 | 150 | 100 | 80 | 60 | 40 | 20 | 10 |

|---|---|---|---|---|---|---|---|---|

| Width W | 4、6、8 | 5、6 | 5 | 5、6 | 8 | 8 | 7 | 5 |

| Height H | 6、7 | 6、7 | 5 | 6、7 | 8 | 8 | 8 | 5 |

| Width C | 1.2、1.5 | 1.2、1.5 | 1.2、 | 1.2、1.5 | 2 | 2 | 2 | 1 |

| Height B | 3.5、4 | 3.5、4 | 3 | 3.5、4 | 4 | 4 | 4 | 3 |

| Grit size | 60# 80# 100# 120# 180# 200# 280# 300#350# 400# 600# 700# 800# 1000# | |||||||

Our Honing Stones can support Gehring, Nagel, Sunnen, Nissin, Ari-Hone and other types of Honing machines. Special purpose honing stone can be available upon request.

Preci-Hone Horizontal Honing Mandrels & Accessories

Standard Mandrels series

.jpg)

Carbide Shoe Mandrels (Y series)

Soft Shoe Mandrels (S series)

Stone Retainers and Wedges

Adapters

Honing Heads-Horizontal Honing heads

Honing heads is also called Honing holders.For workpieces with bore diameter larger than 14mm, Honing mandrel can be modified to multi-stone honing head. We are equipped without exception to supply honing tools for every type of machine and tooling in use today.This type of honing head is suitable for Connecting Rods bore,Forks bore and Sewing Machine Parts Honing.

Honing Heads-Vertical Honing Heads

Honing Heads support various Honing machines, suitable for Hydraulic Valve Bore and Cryogenic Compressor Cylinder Bore Honing, as well as Shaft Bore honing.

Honing Heads used on Nissin Honing Machines, suitable for Fuel Injection Nozzle and Pump Bore, Gear Bore Honing.

Honing Heads used on Nagel, Gehring and China-made Honing machines, suitable for Cylinder Bore and Connecting Rod Bore honing.

The Metal Bond Diamond and CBN Honing Stone and Honing Stick from our company features longer life, higher Honing efficiency and cost effective, they can be used on Sunnen, Nissin, Nagel and Gehring Honing Machines, because the wide use in the auto parts (Connecting Rod, Cylinder, Fork, Rocker Arm), Sewing Parts, Mould Making, Carbide Tooling and Compressor Industry welcomed by many foreign customers.

Gehring type Diamond Honing Stones

| L | 125 | 120 | 100 | 100 | 80 | 70 | 60 | 25 | 18 |

|---|---|---|---|---|---|---|---|---|---|

| Type | B | A | A | B | C | B | A | C | C |

| W | 6.5 | 4 | 4 | 6.5 | 8 | 6 | 2.4 | 2 | 2 |

| H | 7 | 6 | 6 | 7 | 8 | 6 | 4 | 2 | 2 |

| c | 2 | 2 | 1.6 | ||||||

| h | 4 | 2 | 2 | 4 | 3 | 2 |

- A-Standard type

- B— Slot type

- C— Solid type

- L-Length

- W-Width

- H-Height

- c- Slot width

- h- Slot depth

- h- Abrasives thickness

- Ex. L100W6.5H7c2h4 NM55

The outstanding performance of the Stone ensures the Honing of even the most difficult materials,that until now,have resisted cutting by any method.They significantly improve cutting action,overall production rates and Abrasive life over other Abrasive available.Most of the popular tool steels can be honed as easily as ordinary hardened steel.The dimension of the Diamond Honing Stone can be available on your request,our produducts welcomed by customers from Detroit, MI,USA,Toyota from Japan,Stuttgart from Germany,Torin from Italy,Wolfsburg,Tokyo from Japan,Paris from France,Birmingham from UK and other Automotive Industry related areas.

Diamond Wheels for the Glass & Ceramics

Diamond Lens Grinding Wheels

Diamond Pencil Edging Wheels

Diamond Bevelling Wheels

Diamond Glass Cutting Wheels

Diamond Core Drills for Glass

Diamond Pellets for Lens

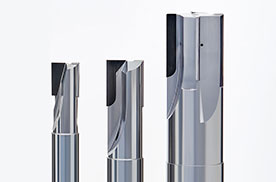

PCD & PCBN Tools for the Automobile Sector

PCD & PCBN Reamer

PCD & PCBN Grooving Tools

Diamond Core Drills & Segments

Diamond Concrete Drilling Tools

| Diameter | Length | Connection Type | Thickness | Size of Segment | Number of Segment |

|---|---|---|---|---|---|

| 12 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x12 | 2 |

| 20 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x20 | 2 |

| 25 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x20 | 3 |

| 33 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x26 | 3 |

| 42 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x25 | 4 |

| 52 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x28 | 5 |

| 62 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x28 | 5 |

| 72 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x28 | 6 |

| 82 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x27 | 7 |

| 92 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x27 | 8 |

| 102 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x27 | 9 |

| 112 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x27 | 9 |

| 122 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x26 | 10 |

| 132 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x26 | 12 |

| 152 mm | 450 mm | 1 1/4" | 2 mm | 3,5x8x26 | 13 |

| 162 mm | 450 mm | 1 1/4" | 2,5 mm | 3,5x8x26 | 13 |

| 182 mm | 450 mm | 1 1/4" | 2,5 mm | 4,5x8x26 | 14 |

| 202 mm | 450 mm | 1 1/4" | 2,5 mm | 4,5x8x26 | 16 |

| 225 mm | 450 mm | 1 1/4" | 3 mm | 4,5x8x26 | 17 |

| 250 mm | 450 mm | 1 1/4" | 3 mm | 4,5x8x26 | 17 |

| 300 mm | 450 mm | 1 1/4" | 3 mm | 4,5x8x26 | 18 |

| 320 mm | 450 mm | 1 1/4" | 3 mm | 4,5x8x26 | 18 |

| 350 mm | 450 mm | 1 1/4" | 3 mm | 4,5x8x26 | 20 |

| 400 mm | 450 mm | 1 1/4" | 3 mm | 4,5x8x26 | 22 |

Address

Kristal Abrasives

No: 35, 1st Cross Street,

Saravana Nagar, Perungudi,

Chennai-600 096.